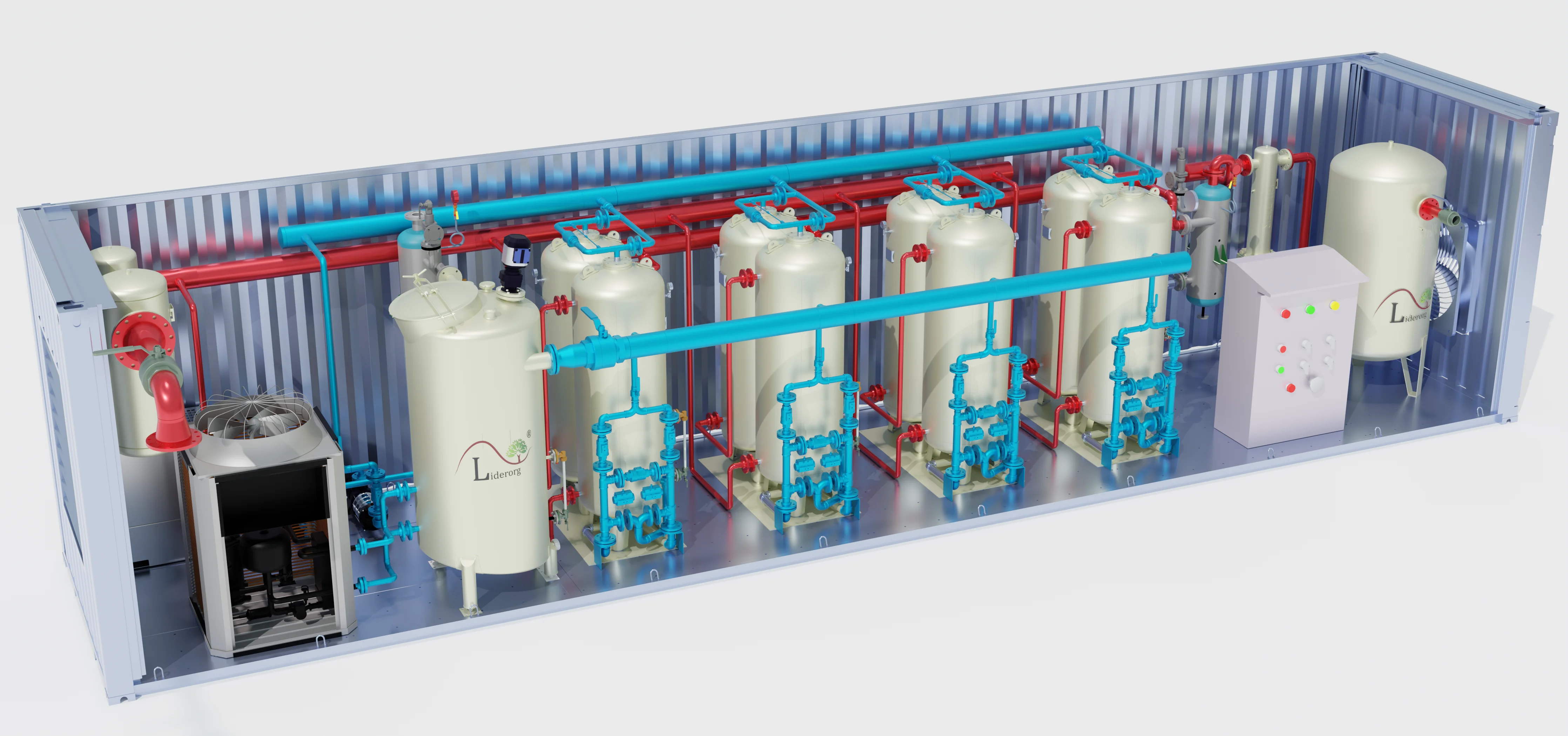

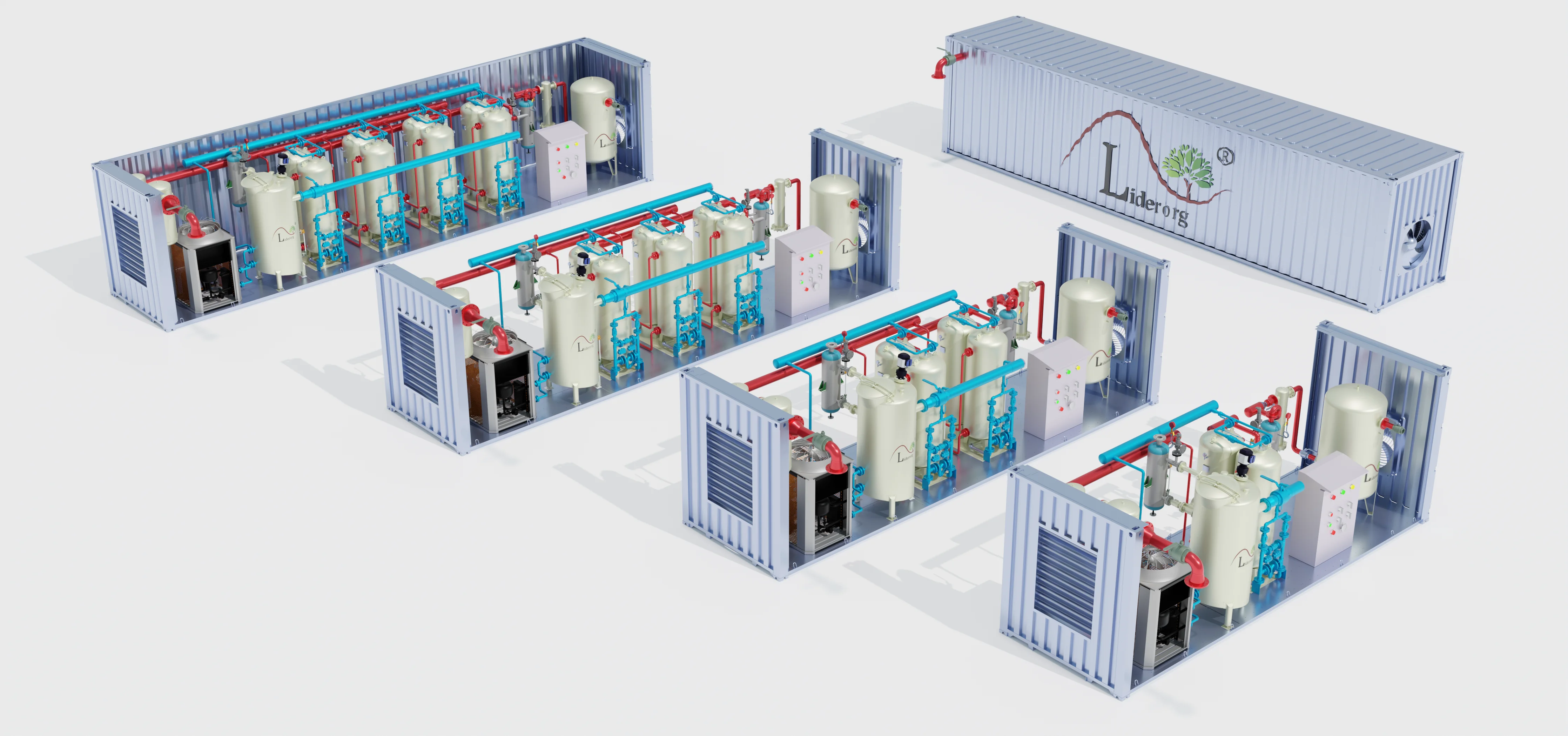

Biogas Purification and Scrubbing Unit

- Summary: Biogas consists of many unwanted impurities such as Carbon dioxide, Hydrogen Sulphide, Oxygen, Siloxanes, Moisture, Mercaptans, etc. Depending on the end usage or applicable standards, either some or all impurities are to be removed from the gases with help of Biogas Purification System.

- Filters in our system: Particulate filter, Hydrogen Sulphide Scrubber, Siloxanes remover, Carbon dioxide remover, Moisture remover

- Methane Loss: Less than 1% while maintaining more than 95% methane purity (By volume)

- Output Methane Purity: Up-to 99.999% can be achieved

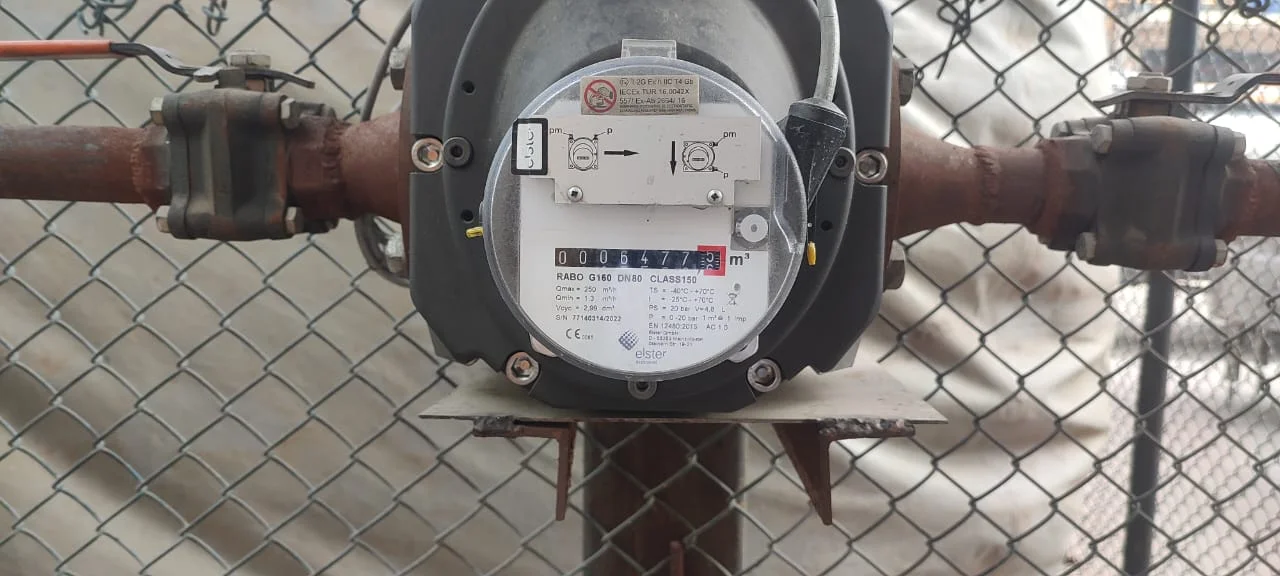

- Range: 25 SCM per hour to 5,000 SCM per hour

Why choose our system?

- Low revenue leakage: Less than 1% methane loss is maintained while keeping the power consumption at minimum i.e., up-to 25% more revenue from gas sale.

- Sustained Purity over lifetime: The active media is nothing but 99% water. As compared to imported Zeolites (good quality) which do not have any warranty and face degradation over lifetime, our media is locally available, even if degradation is observed, replacing the media is as easy and cheap as your tap water!

- Low water consumption: Ours is a Patent Pending system designed to use as low water as possible, so much so that operation in low water availability area will also be viable.

- Safety: In the future versions, we have planned to have the whole system hermetically sealed so that in case of any leakage/failure, the gas can be redirected to the flare or other safe space.

- Affordable: Our systems are up-to 20% cheaper than contemporary standard purification systems with low methane loss ratings.

- Less space required: Our systems use very low space and is entirely skid mounted, in future versions, the system will also be completely isolated and hermetically sealed.

- Up-gradation: We learn from our mistakes, and we make sure to apply those learning to all our sites, both existing and upcoming. We will post sale essential up-gradation to you free of cost.

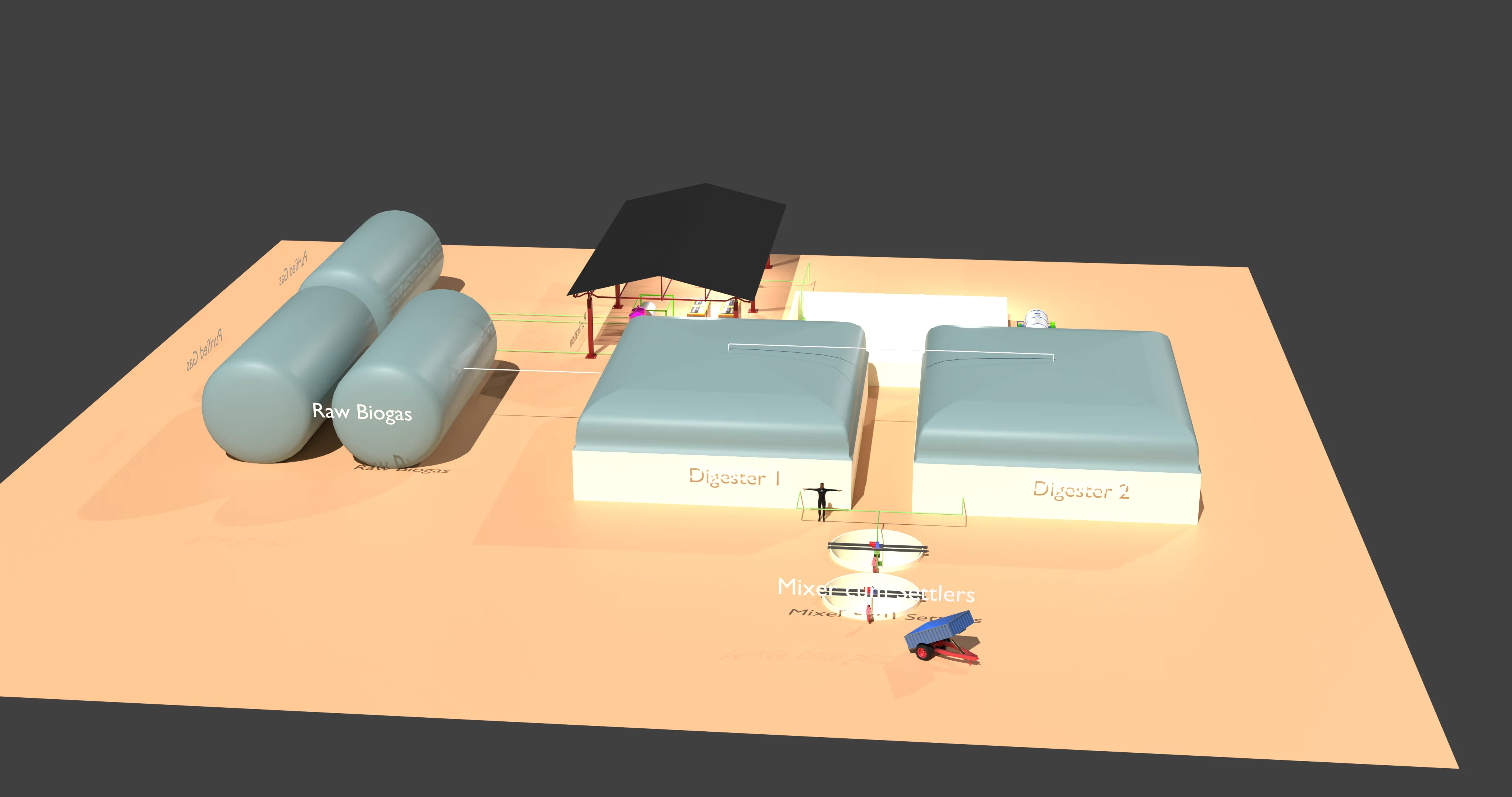

MCMF Based CBG/ Power/ Fuel Distribution Plants

- Types : Home Based Biogas Plants, Heat Energy Biogas Plants, Biogas Power Plants, RNG (Renewable Natural Gas)/ CBG/ Bio-CNG Plants

- Components : A Biogas plant have three component: Biogas Production, Biogas Purification and Distribution, Fertilizer handling. You might see very identical setup inCBG/RNG, Biogas Power Plants, and Biogas Fuel Distribution Plants, the only differentiator of CBG from other plant is mandatory removal of Carbon dioxide from biogas to take it to Natural Gas level.

- Raw materials : Any organic waste and ETP/STP water(with high organic content) can be used in Biogas Plants. Some of the most popular feeds for Biogas Plants are: Cattle Dung, Poultry Waste, ETP/STP water, Napier/Elephant Grass, Food Waste, MSW Waste, Energy crops, etc.

FAQs

- What is Biogas? : Biogas is natural bi-product of anaerobic respiration. Biogas contains 50-65% methane. Biogas can be directly used in cooking purposes or Co-heat and Power Generation after Hydrogen Sulphide and Siloxanes Scrubbing, although the significant carbon dioxide does reduce the burning efficiency up-to 5 to 10%. To increase efficiency even more, the gas can be purified to Natural gas grade, although it does increase the project cost and energy consumption of the plant.

- What's CBG? : CBG Plant is nothing but Biogas Plant where Biogas is purified to Natural Gas level and that gas is then supplied for end use. Other common names from CBG plants are RNG (Renewable Natural Gas) Plant, Bio-CNG Plant, Purified Biogas Plant.

- What's MCMF? : MCMF, i.e., Multi Chamber Mass Flow Type Reactor is technology especially designed for Anaerobic Reaction, keeping in mind the various pH stages required for good Biogas formation. The digester does not require any electrical input to operate and is designed to be scum and dead zone resistant. The result is up-to 10% more methane output with 99% less electrical energy expense.

- What's the difference between CBG/ Power/ Fuel Distribution? : With mandatory Hydrogen Sulphide scrubbing in all type of Plants, If a Biogas Plant have a Purification unit that upgrades the Biogas to Natural Gas level, it is CBG/RNG Plant. If it have electrical generator, It is Power Plant (Power Plants may or may not have Natural Gas level Purification to improve efficiency). If the Sweetened Biogas or Purified Biogas is being distributed to community or boilers or home kitchen, then the plant is fuel distribution type.

Why Choose us?

- Money saving : Up-to 30% on initial investment can be reduced by installing plants using our technology while maintaining equal if not more output .

- Minimum Electrical Input : Traditional Plants have CSTR digester with double membrane balloons on top, resulting in massive electrical energy consumption. Our MCMF system does not have any moving part and only have single membrane roof, along with that for local grid injection, no extra compressor is required in our plants. Hence the energy saving.

- Up-to 50% more operating margin : Up to 90% less electrical expense, low maintenance cost, Less breakdown, Low EMI amount for the project leads to higher operating margin

- Low methane loss : Our patent pending system makes sure of minimum methane loss.

- Minimum Maintenance : Due to absence of any unaccessible moving parts, or any moving parts at all and resistance to scum and dead zone formation, the breakdown and maintenance of the MCMF Digester are minimum with sustained output.

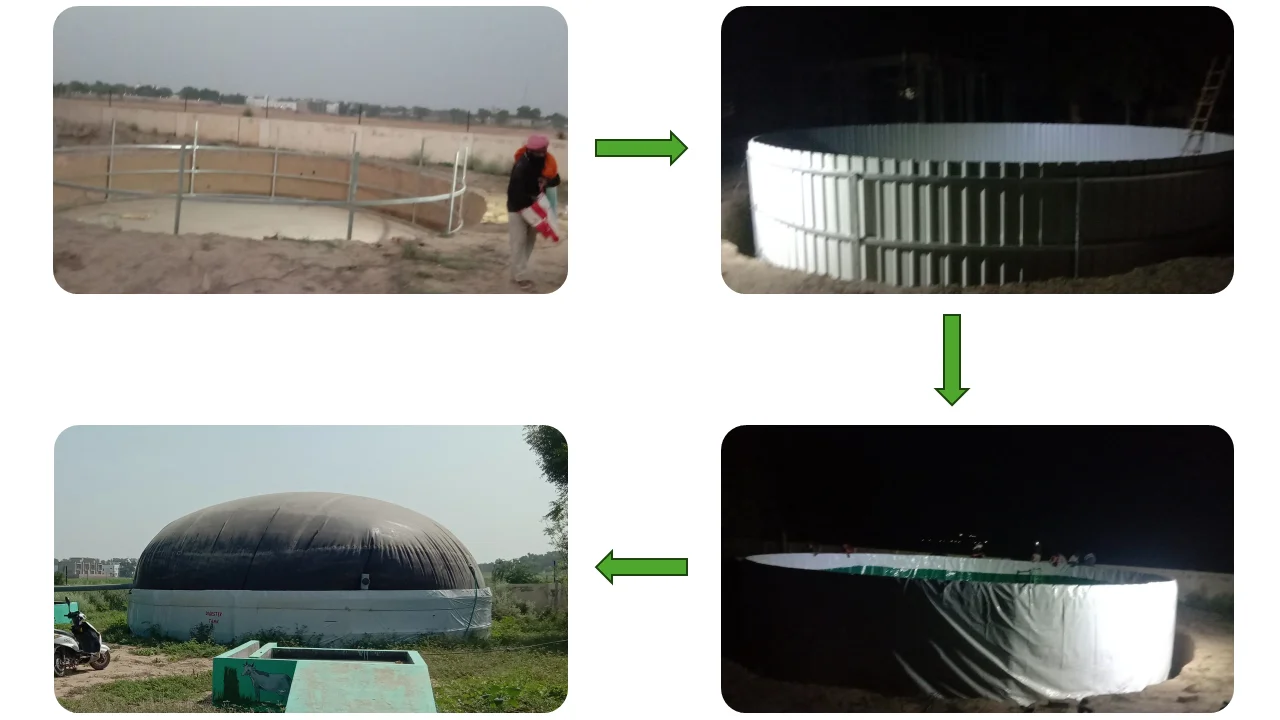

- Fast Installation : Very fast installation due to minimum civil work and on site assembly.

- Safer investment option : Due to high operating margin, you, the investor has more buffer zone to tackle any challenges that arises in the market, be it raw material or end product market.

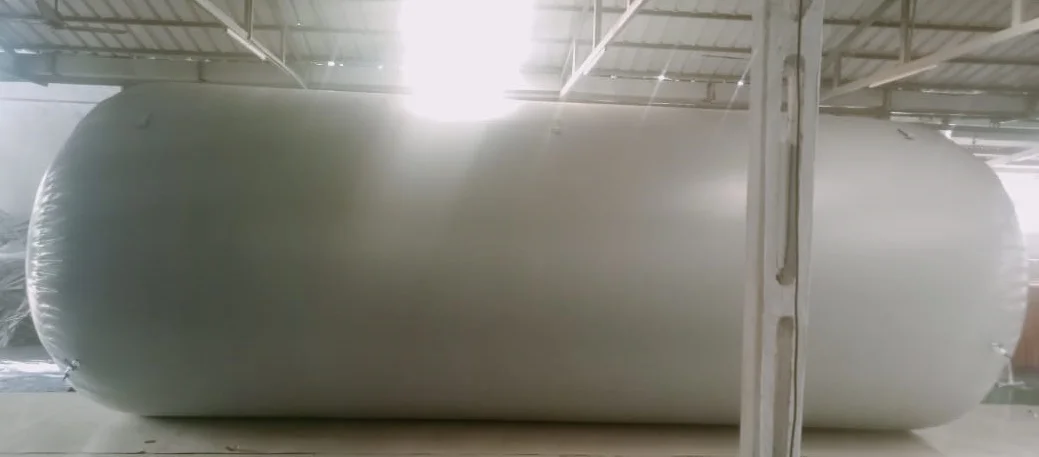

On-site Assembled MCMF Digester

- What's MCMF? : MCMF, i.e., Multi Chamber Mass Flow Type Reactor is technology especially designed for Anaerobic Reaction, keeping in mind the various pH stages required for good Biogas formation. The digester does not require any electrical input to operate and is designed to be scum and dead zone resistant. The result is up-to 10% more methane output with 99% less electrical energy expense.

- History of MCMF : MCMF system is not entirely new system, it has been implemented in India 5,000 years back as seen in the Indus Valley excavation. MCMF is a type of Moving Bed High Rate Anaerobic Reactor best suited for anaerobic reaction.

- On-site Assembled MCMF Digester : On-site assembled digester is a in-house developed technology by Liderorg where prefabricated digester is assembled on site. With three layer of safety and support, the civil work requirement is very little.

Why choose On-Site Assembled MCMF Digester over CSTR or other traditional digester?

- More Biogas Production : Since the MCMF digester designed by us efficiently keep the different pH zones separated, the Biogas Generation is stable and more compared to traditional methods.

- Very Quick Installations : On-site assembled Biogas Plants can be installed in just 1-5 days depending on the size

- Low Hydrogen Sulphide Output : Due to separated regions.

- No operating expense : As there are no moving parts

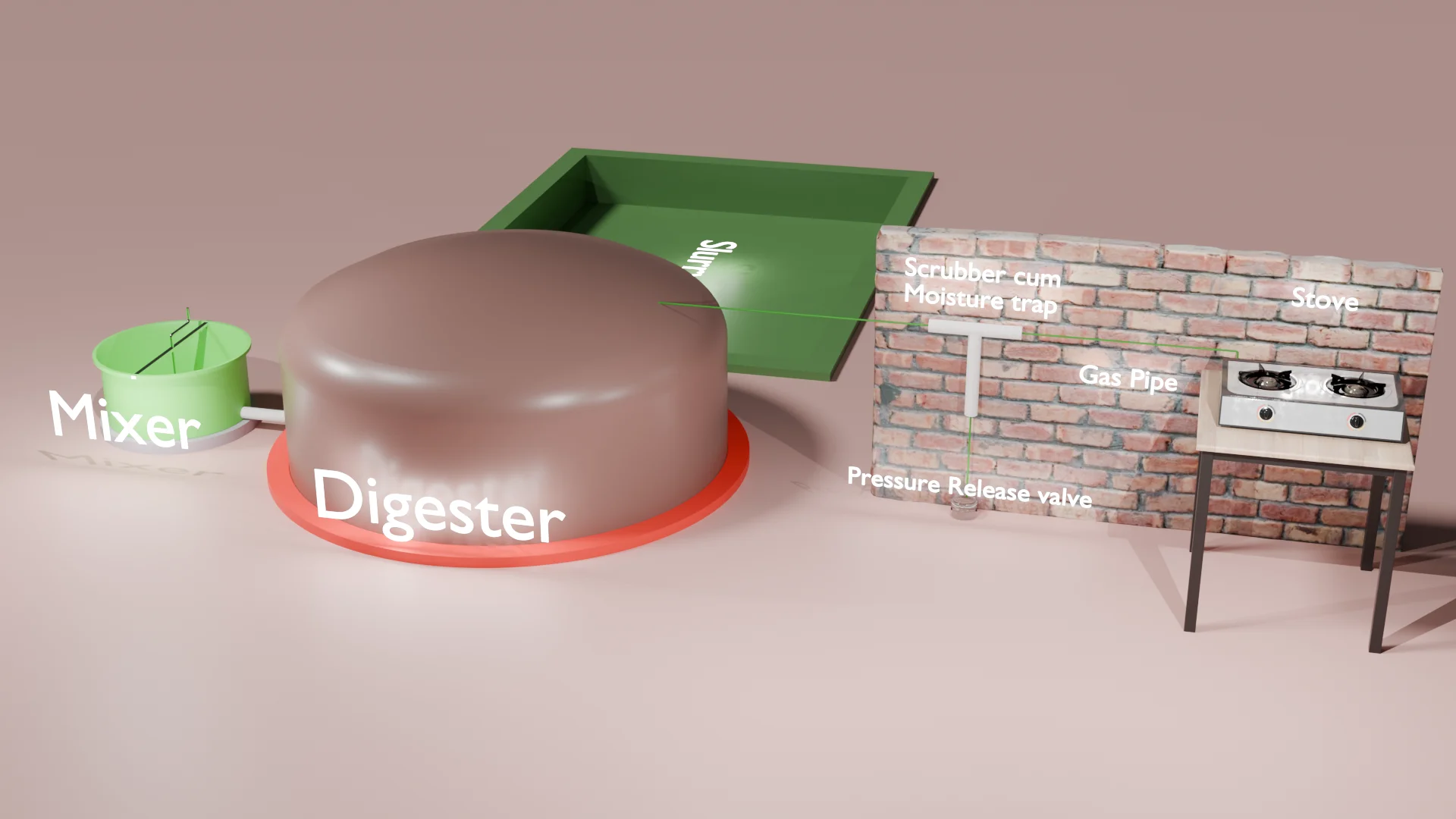

Home Based Biogas Plants

- A modular solution to meet the demand of all size homes and Farms.

- Reliability : Less than 0.01% failure rate in our 12,000+ installations.

- Reduce the carbon emission at source

- Get your money back in just 1 year.

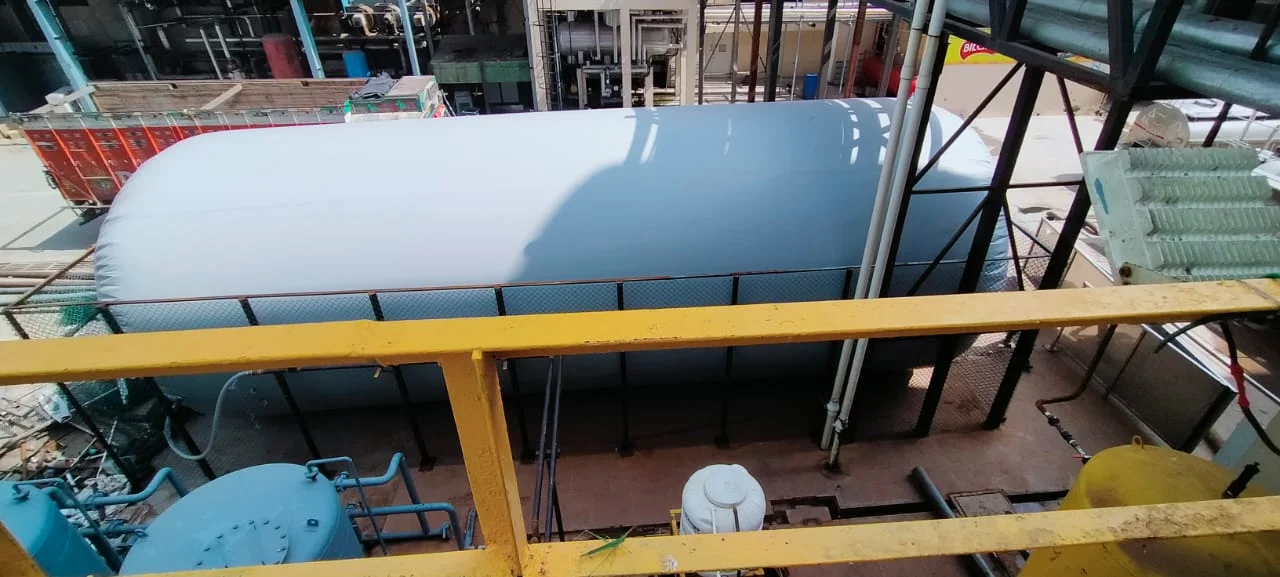

Biogas Storage Balloons

- MOC : PVC coated fabric

- Thickness : 750 to 1200 GSM

- Size : 2 cubic meters to 20,000 cubic meters

- Special : Fire Resistant

Why Choose us?

- Cost effective : We provide you the best product at competitive rate.

- Special Advanced System : Essentially can replace the double membranes.

- Fire Resistant : Extremely slow fire propagation.

- Tear resistant : Due to reinforced fabric.

Other Products

- Agitators and Mixers : For making of slurry.

- Pretreatment Set : Lignin & Cellulose rich raw materials need to be Pre-treated, either mechanically or chemically or biologically to get proper biogas production.

- Fertilizer Machine : We provide chambered filter press for solid and liquid separation as it is more efficient and less prone to breakdown, albeit requires more oversight and intervention.

- Fertilizer Post Processing : To convert the organic fertilizer to PROM that can out-compete the chemical DAP. It increases the sale price from INR 5/kg to 20-40 /kg. We also provide value enhancer for liquid FOM.

- Safety and Instrument : Balloon safety valve, Flammable gas detector, Hydrogen Sulphide alarms etc.

Products Under Development

- Low cost Power Plant Specific Purification Unit : A very low cost purification only meant to take purity up-to 90%, so that CNG generators can be operated on it effortlessly thus resultantly increasing the reliability of Biogas Power Plants while reducing the overall cost.

- Biogas powered EC engine : An alternate energy generation method.